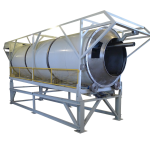

SBKw

CONVECTION ROTARY DRUM DRYER

-

HEATING

gas | oil | pellets | electric

-

CONTROL

automatic

-

AIR FLOW

along the axis

SBKw

CONVECTION ROTARY DRUM DRYER

-

HEATING

gas | oil | pellets | electric

-

CONTROL

automatic

-

AIR FLOW

along the axis

for food granulates, agricultural and forestry products, minerals, waste plant products, pomace

fully automatic, exhaust and circulation valves operated by humidity and temperature sensors to ensure best results whilst achieving the best possible energy efficiency, intuitive and programmable user interface, downloadable records, delayed start, remote connectivity

BUILD MATERIAL | ||

BODY | stainless steel or galvanised | |

FRAME | galvanised | |

INSULATION | mineral wool and polyurethane foam | |

| ||

CONTROLS | ||

INPUT | air temperature airflow speed exhaust air humidity time | |

MEASUREMENTS

| temperature exhaust air humidity time | |

FUNCTIONALITY

| Siemens automation with 7″ touchscreen interface drying program can be divided into 3 stages with different parameters remote connectivity via LAN, WIFI or GSM | |

| ||

HEATING POWER | [kW] | 200 |

DRUM VOLUME | [m3] | 6 |

DIMENSIONS | [mm] | 2000/2000/6000 |

for food granulates, agricultural and forestry products, minerals, waste plant products, pomace

fully automatic, exhaust and circulation valves operated by humidity and temperature sensors to ensure best results whilst achieving the best possible energy efficiency, intuitive and programmable user interface, downloadable records, delayed start, remote connectivity

BUILD MATERIAL | ||

BODY | stainless steel or galvanised | |

FRAME | galvanised | |

INSULATION | mineral wool and polyurethane foam | |

CONTROLS | ||

INPUT | air temperature airflow speed exhaust air humidity time | |

MEASUREMENTS | temperature exhaust air humidity time | |

FUNCTIONALITY | Siemens automation with 7″ touchscreen interface drying program can be divided into 3 stages with different parameters remote connectivity via LAN, WIFI or GSM | |

HEATING POWER | [kW] | 200 |

DRUM VOLUME | [m3] | 6 |

DIMENSIONS | [mm] | 2000/2000/6000 |

- up to 3000 kg

SINGLE BATCH SIZE

guide values